Heat exchangers are involved in a variety of application areas, such as water treatment, resource refinery, nuclear power, food and beverage production, refrigeration, and more.

Heat exchanger analysis involves the transfer of heat between fluids and solids, where the fluids carry energy over large distances and the solids separate the fluids so that they can exchange energy without mixing. Heat exchangers are used in a wide range of application areas, such as water treatment, resource refinery, nuclear power, food and beverage production, refrigeration, and more.

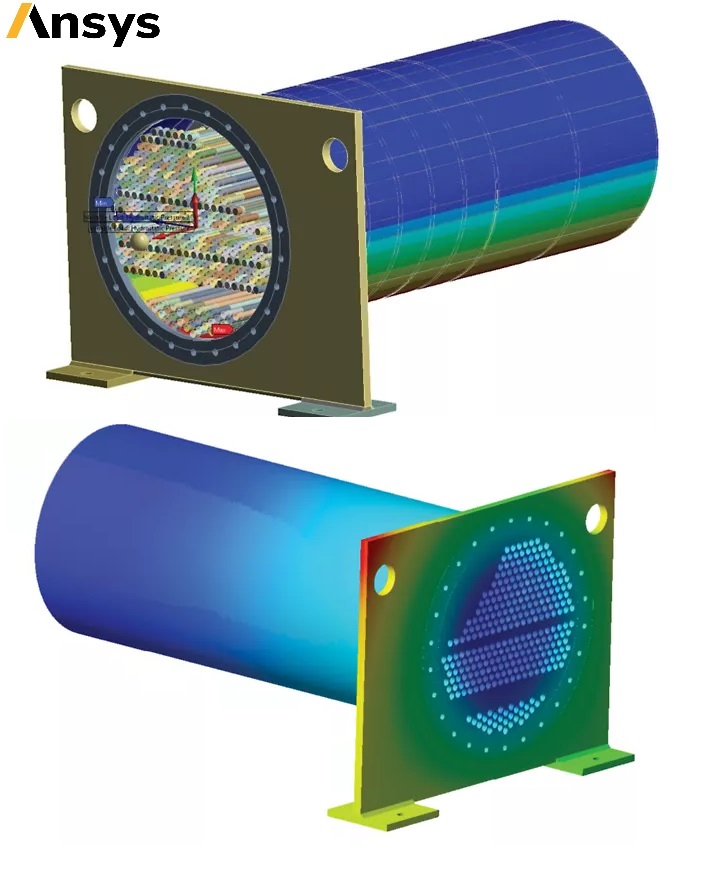

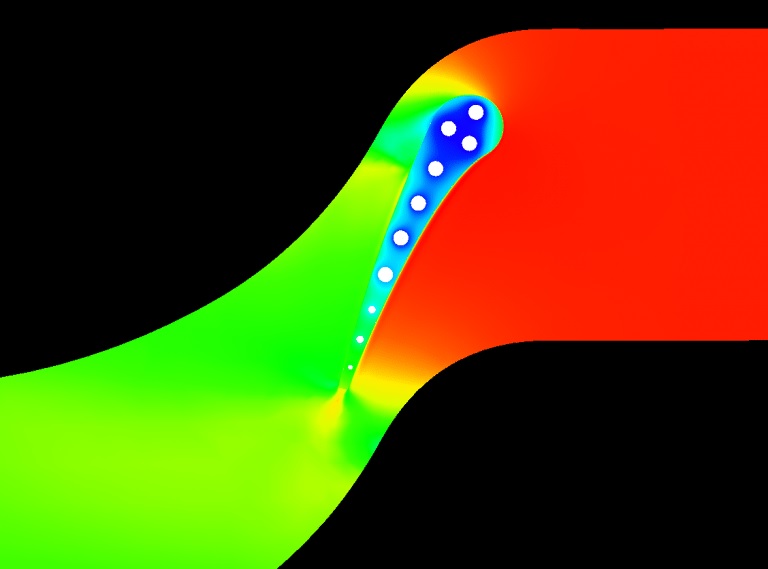

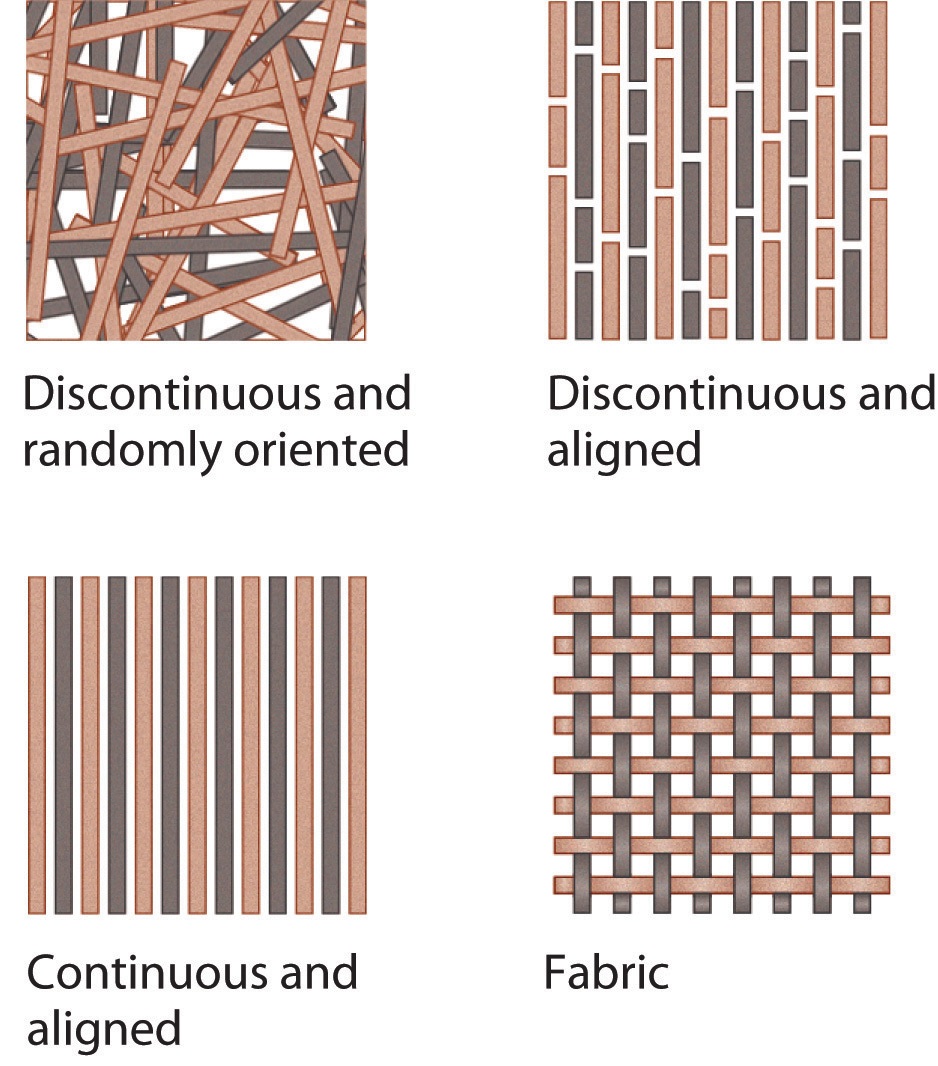

In a heat exchanger, two fluids are separated by a solid surface, which can be in the form of tubes, plates, or fins. One fluid flows through the tubes or passages, while the other flows around the tubes or passages. Heat is transferred from the hot fluid to the cold fluid through the solid surface, resulting in a temperature difference between the two fluids.

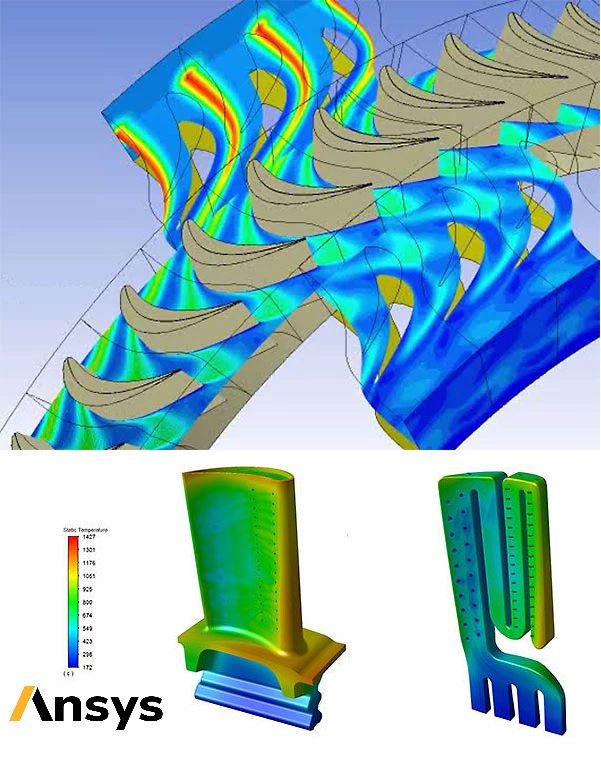

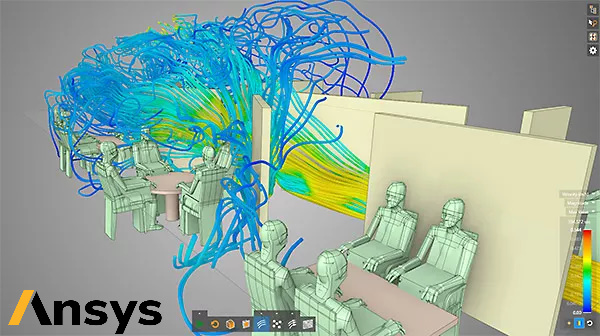

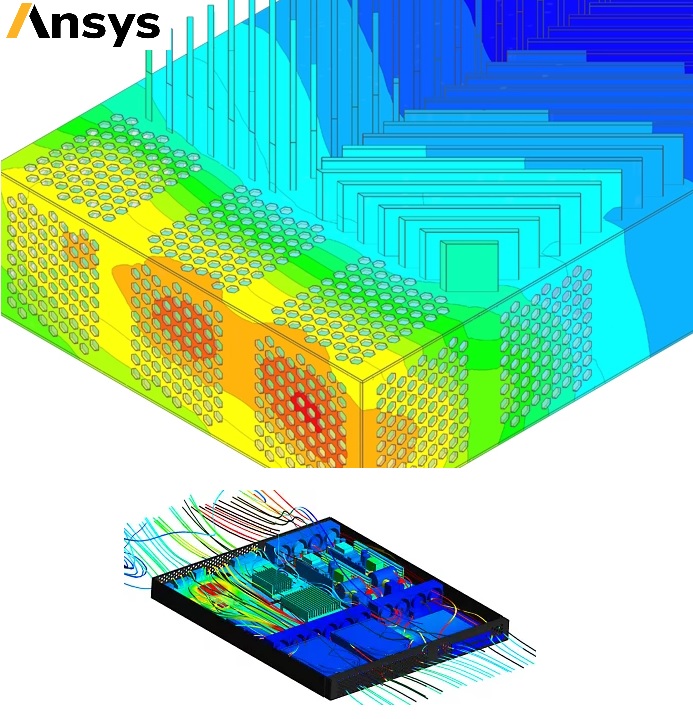

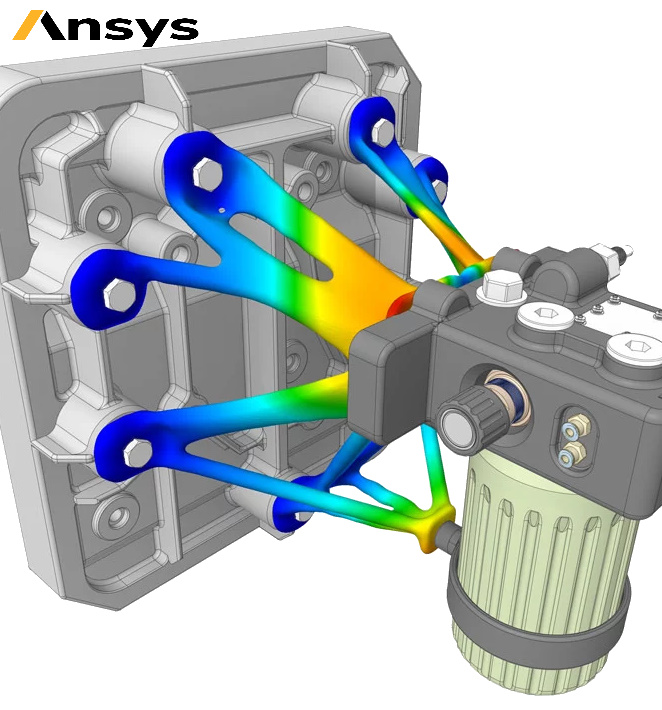

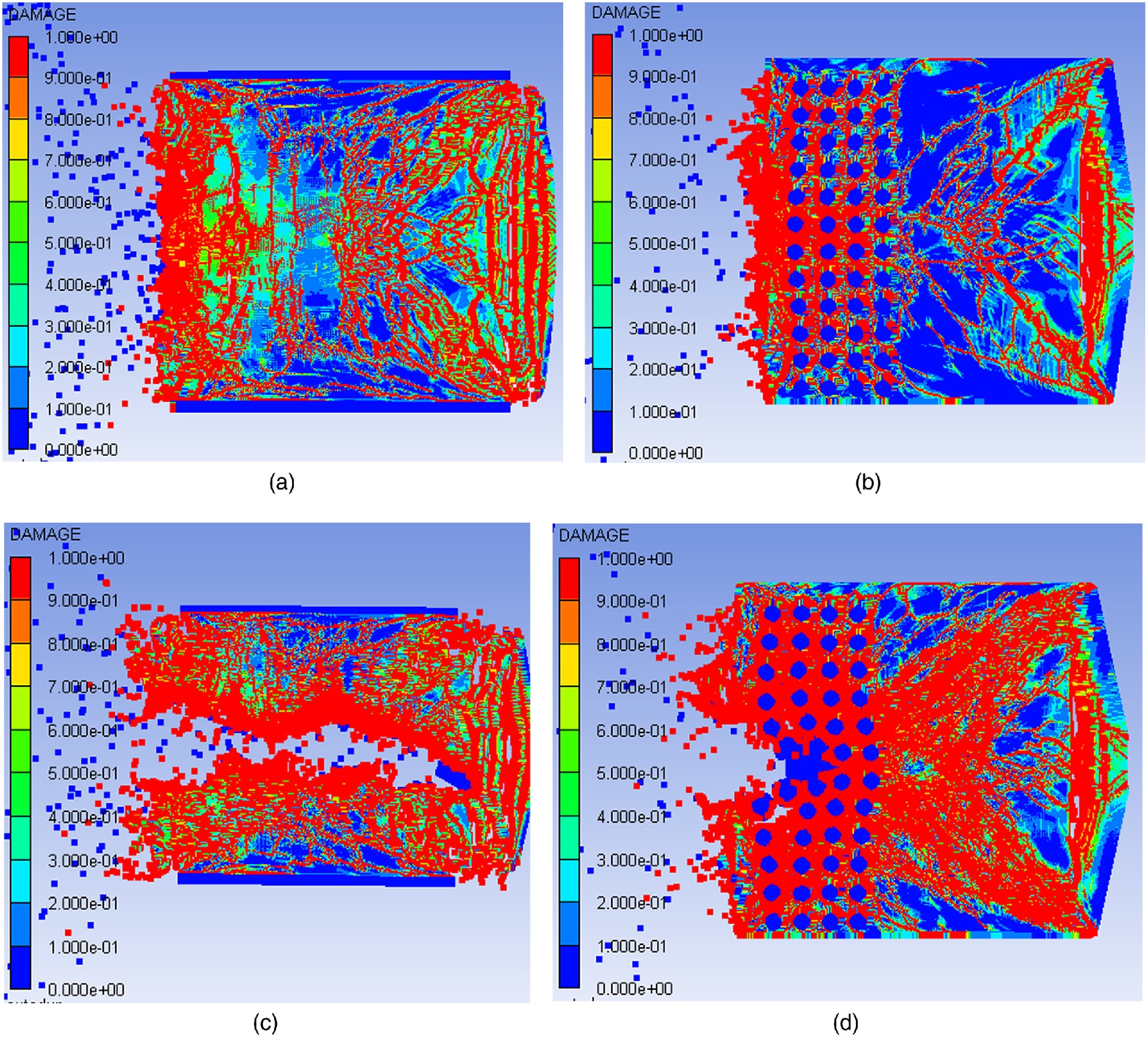

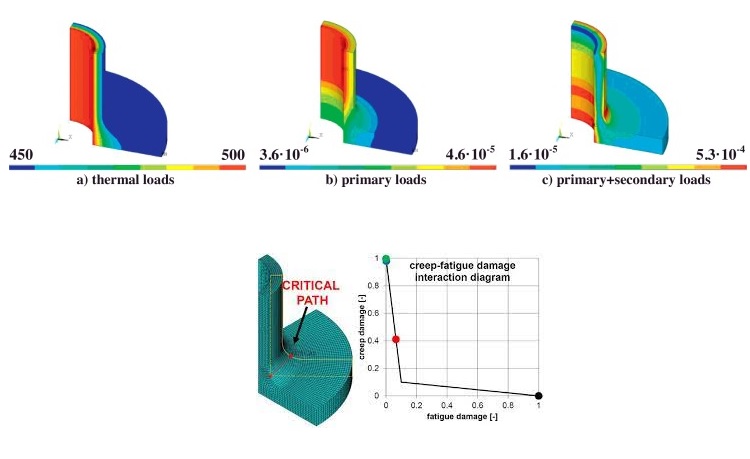

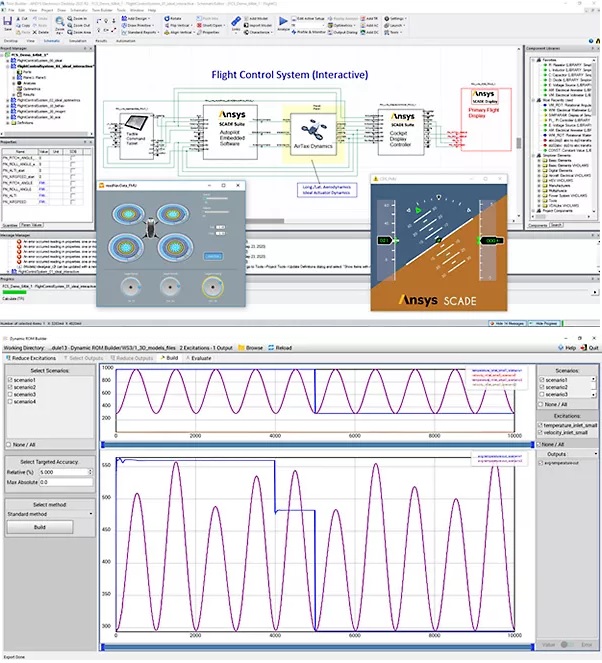

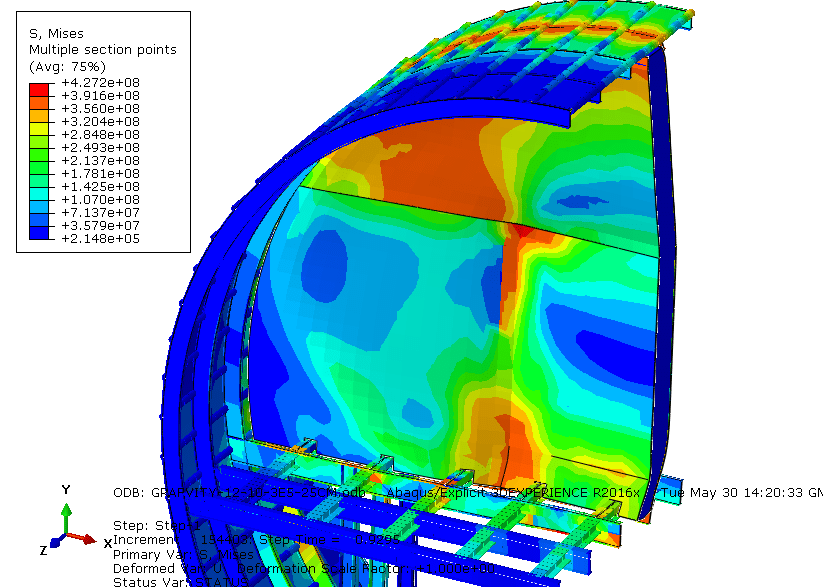

The performance of a heat exchanger can be analyzed using a variety of methods, including CFD simulations, FEA simulations, and empirical correlations. CFD simulations can be used to model the flow of fluids through the heat exchanger and predict the heat transfer coefficient, while FEA simulations can be used to model the temperature distribution in the solid surface and predict the thermal stresses and deformations.

Empirical correlations, such as the Nusselt number and the Reynolds number, can be used to estimate the heat transfer coefficient and pressure drop in the heat exchanger based on experimental data. These correlations are useful for preliminary design and optimization of heat exchangers, but may not be accurate for all flow regimes and geometries.